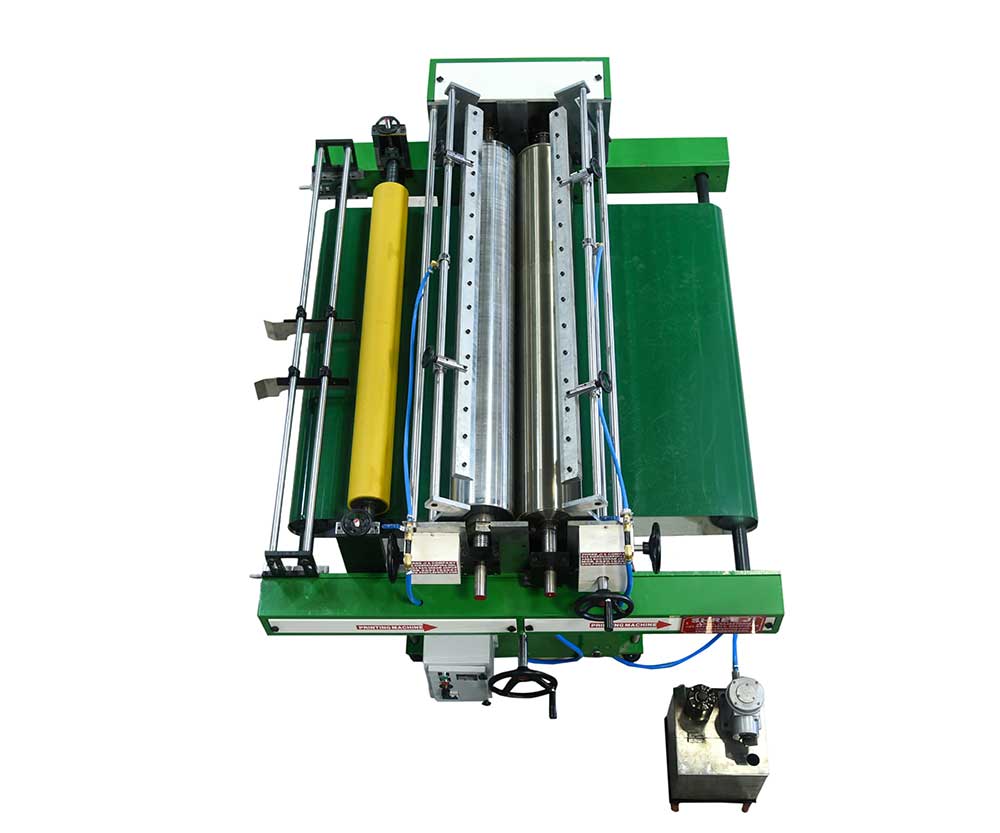

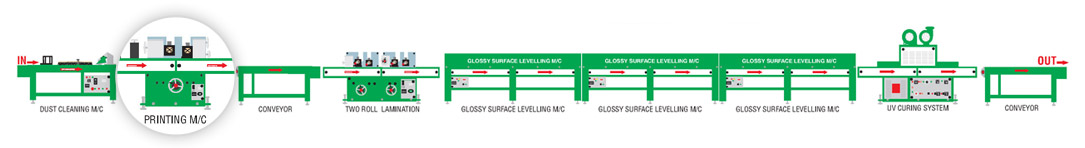

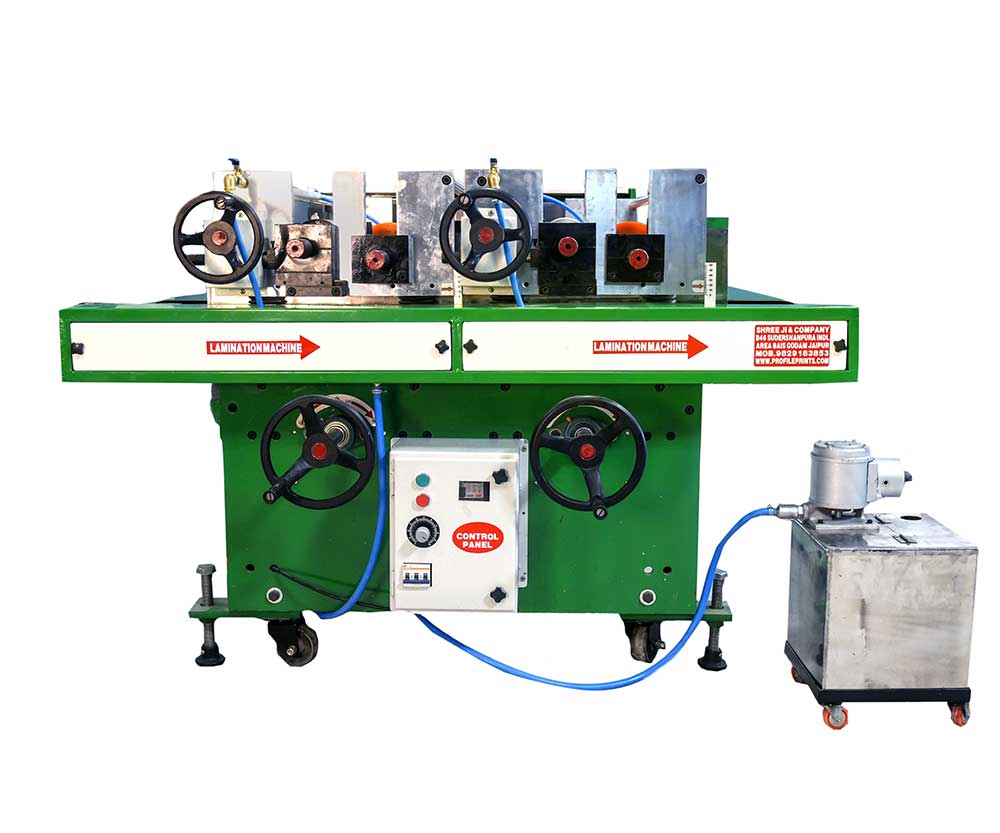

Two Roll UV Coater Machine

Two Roll UV Coater Machine

Technical Parameters

| Title | Category |

|---|---|

| Working Width in mm | 240, 300, 760, 1000, 1300 mm |

| Working Speed | 0-30 mtr/min |

| Profile/Board Thickness | 1-150 mm |

| Electric Power | 2.25 HP |

| Roll Direction | Two Roll Forward Direction |

FEATURES

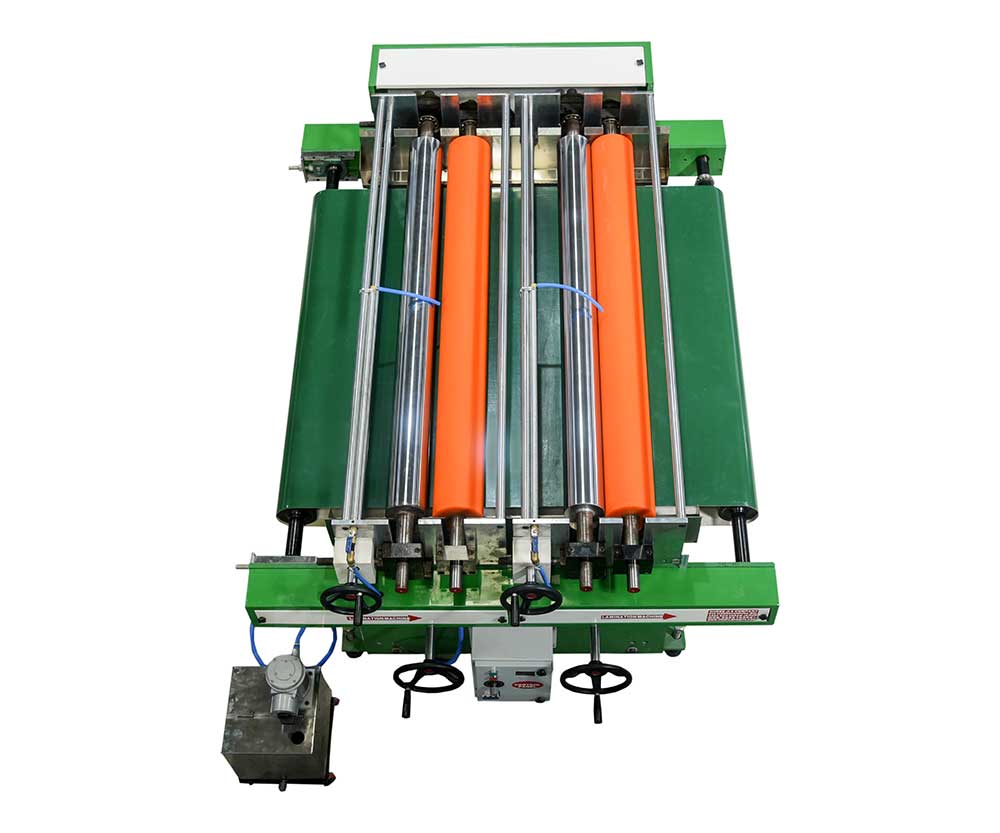

- Especially designed Two roll Coating / lamination machine, two roll gives perfect and uniform lamination which gives hard, glossy and smooth surface finish. It gives far better glossy smooth surface finish, saves valuable UV coating material.

- Two roll coater lamination quality & surface finish is far better than that with single roll coating. UV Material consumption in single roll coating machine is also more as compare double roll coating machine.

- One roll coating / lamination machine is also available if customer wants economical version. UV Material consumption in single roll coating machine is more as compare double roll coating machine.

- This machine is suitable for PVC profile doors, veneer board, plastic extruded sections, wall panel, ceiling panel, foam board, wood, floor, ACP, WPC, Edgeband etc.

- The feeding speed can be adjusted couple with the coating / laminated speed.

- Machine is equipped with two sets of UV lamination roller having abrasive & solvent resistant application rollers and doctor blades are controlled independently which enhance the working precision. The coating thickness can be also be adjusted easily.

- Easy to replace lamination / coating roll one just has to disassemble the locking bushing & replace which is time & labour saving. This machine is designed with easy dismantle structure to make convenient cleaning and maintenance.

- Safe, convenient & rapid system for UV material recycling that too without wastage.

- Coating / lamination machine is available in various effective width and sizes. We can develop machine as per customer specification apart from below given sizes and application